All You Ever Wanted To Know About Boat Propellers

Modern marine propulsion is the forefront of technical development and engineering. Yet no matter how efficient our drive units become, it’s most often up to the propeller to transmit the power to maximise boat performance. Suitable propeller choice and fit-up techniques can turn a poorly handling boat into a masterpiece of nautical matchmaking. There is quite a science to propeller technology with a huge field of choice to find the right prop, but for many boaties it can be the last item on their minds.

The origins of our modern propellers came from the Greek scholar Archimedes who invented a screw type mechanism as an early pumping device for irrigation and bilges, hence named the Archimedes Screw. Even Leonardo De Vinci had a hand in the development of the propeller with his early theoretical concepts of a helicopter.

Yet history tells us that modern propeller design was the invention of a Yale student by the name of David Bushnell, who worked with foundarymen, carpenters, and clock makers in constructing the first modern brass propeller which was used on a Connecticut built submarine in 1755. Whilst there were many attempts to perfect the screw type propeller, it wasn’t until 1838 that the steam powered “SS Archimedes” was built driven purely by a screw propeller, supplanting more traditional paddle drives.

The Essentials of Modern Propellers

Whilst there are many propellers for a multitude of vessels, we'll focus on those for recreational vessels, including displacement cruisers, yachts, ski and wake boats, planing hulls, performance/race boats, as well as shaft, outboard and stern drive alternatives with single or multiple drives.

There are controllable, fixed and variable pitch props, retractable, clever, chopper, left and right hand, counter and contra-rotating, pusher, test, and those with multiple blades. The great majority of props for recreational use are made from stainless steel, aluminium or bronze, with some plastics in low horsepower applications.

Understanding propeller design requires us to familiarise ourselves with some of the terms and forces at work to produce propulsion. Some of these include thrust, pitch, diameter, torque, revolutions, rake, cupping, efficiency and cavitation.

Propeller Terms and Definitions

Pitch: Propeller pitch is the theoretical forward travel distance that a propeller would transit in one unrestricted rotation measured in inches

Thrust: The transfer of the engine horsepower to the water is termed as thrust.

Torque: A measurement of rotational force relative to the RPM usually expressed in Nm (Newton Metres) or ft/lbs in imperial ratings.

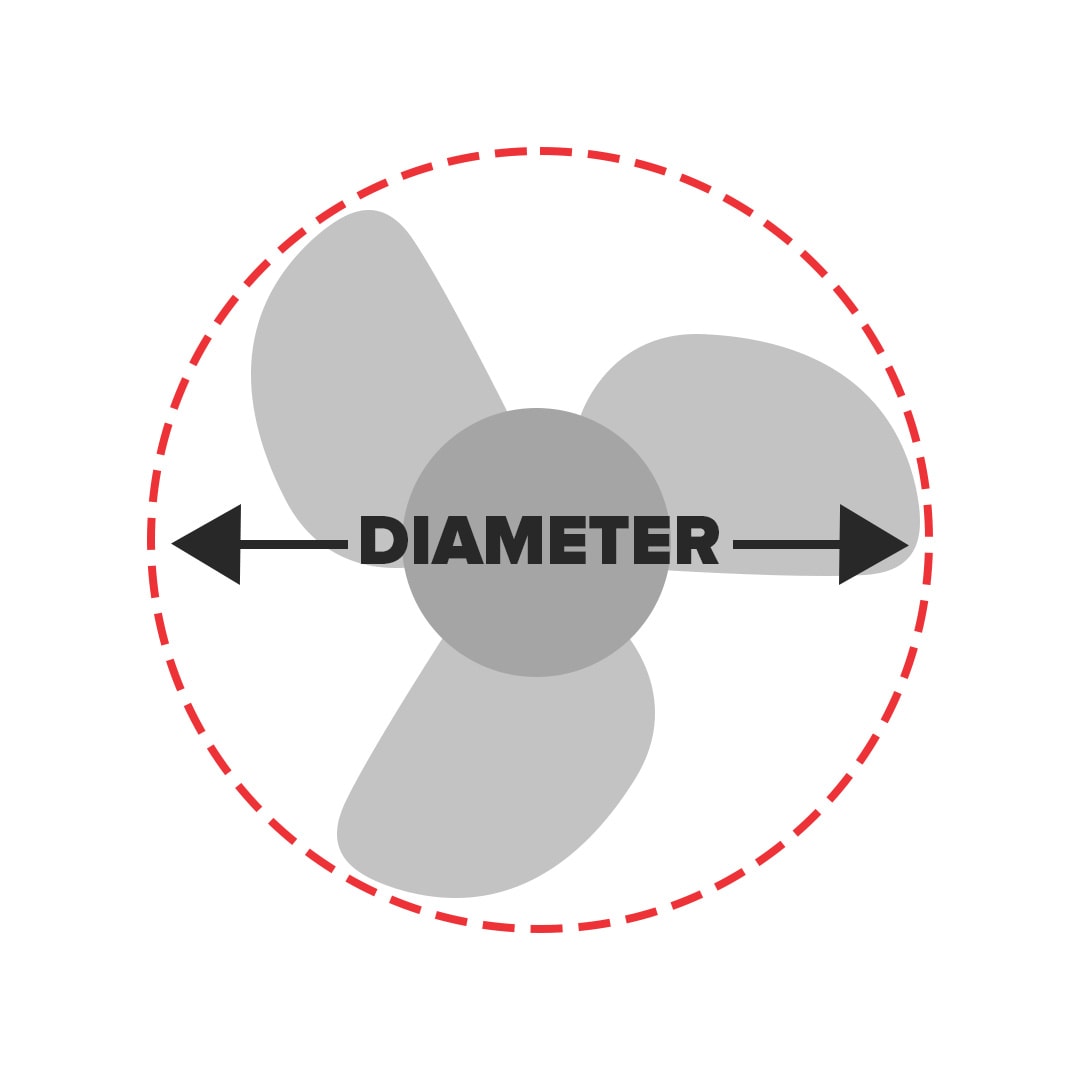

Diameter: Diameter is a measurement of the total width of the propeller across the centre of the prop and is usually given in inches.

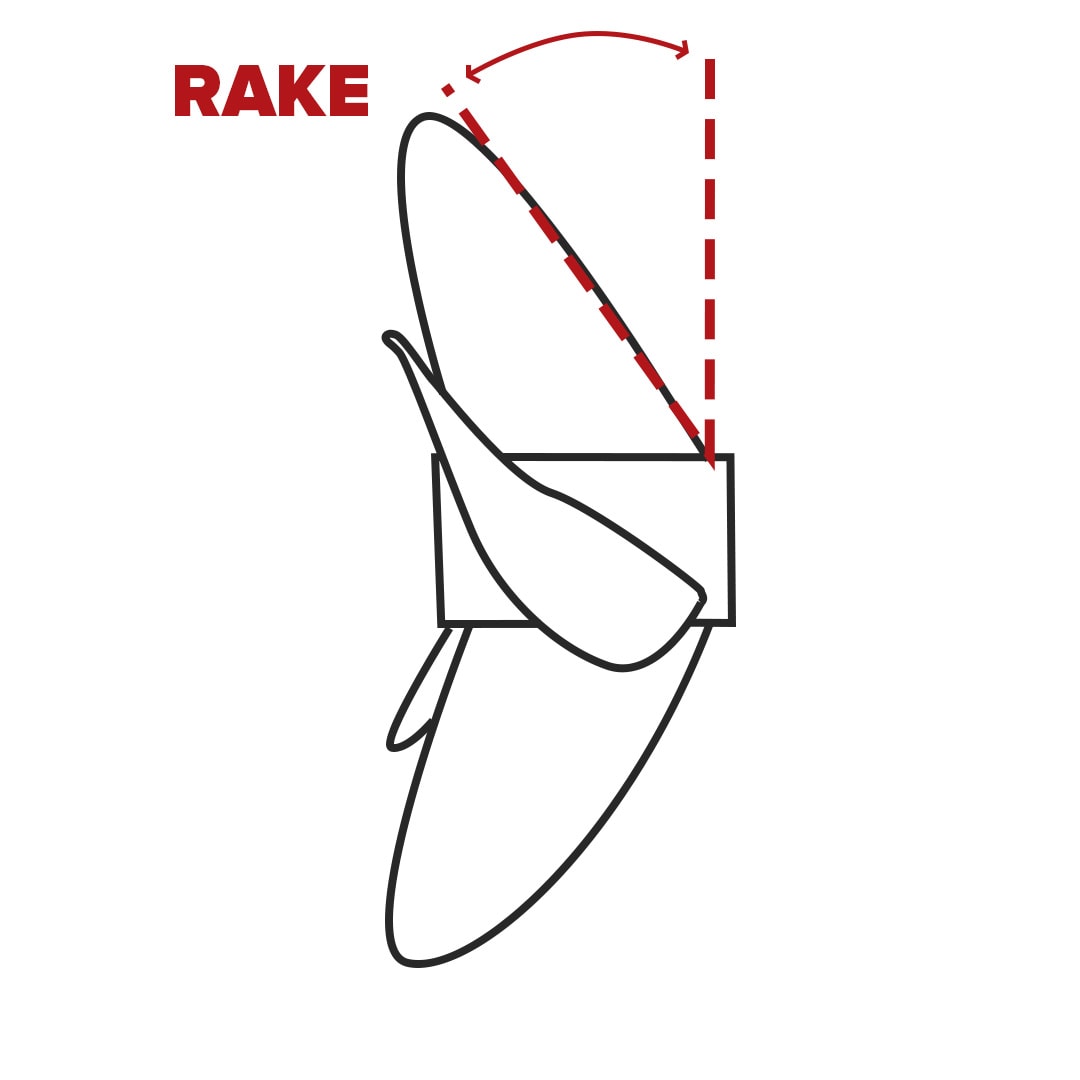

Rake: Rake is the angle of the blades measured perpendicular against the hub or shaft, and is given in degrees

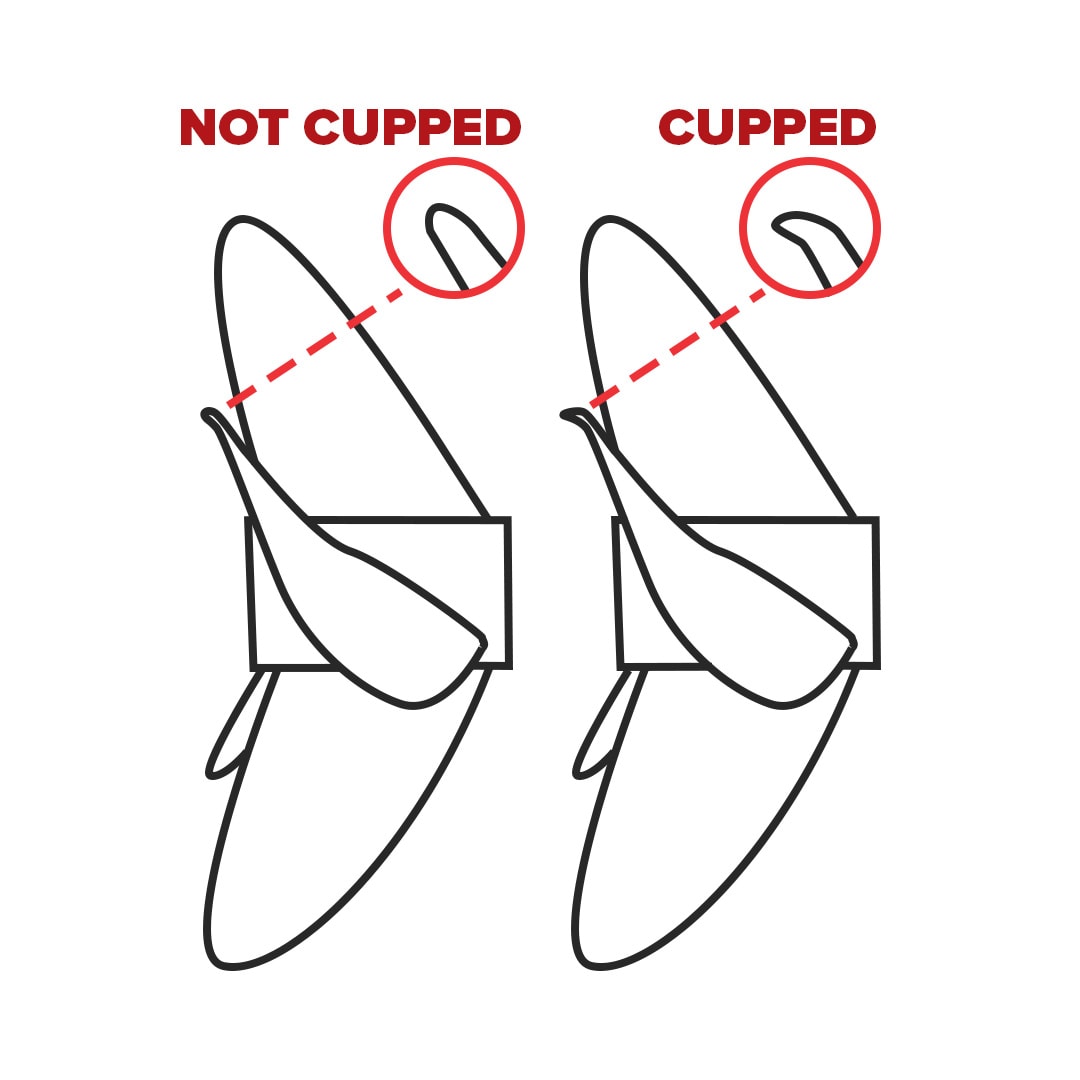

Cupping: Cupping is forging a spoon or curl shape just under the leading edge of the propeller blade which will change the performance without bending or replacing the propeller.

Rotation: A right hand rotation propeller will turn clockwise when viewed from the rear of the vessel and a left hand rotation propeller will turn anti-clockwise.

Revolutions: The speed at which the propeller turns relative to drive speed, given in revolutions per minute (RPM).

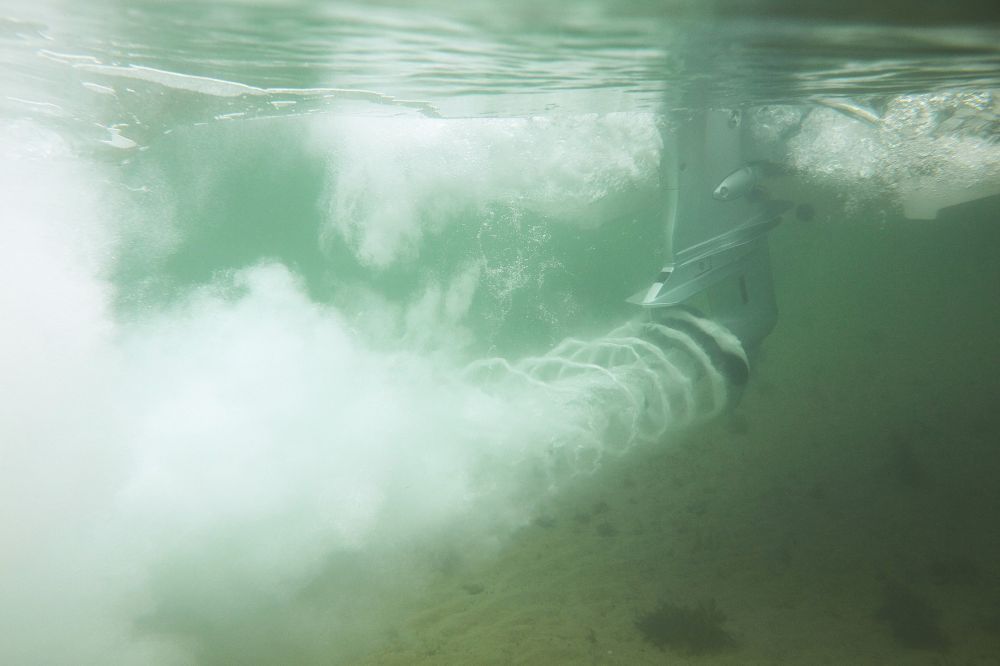

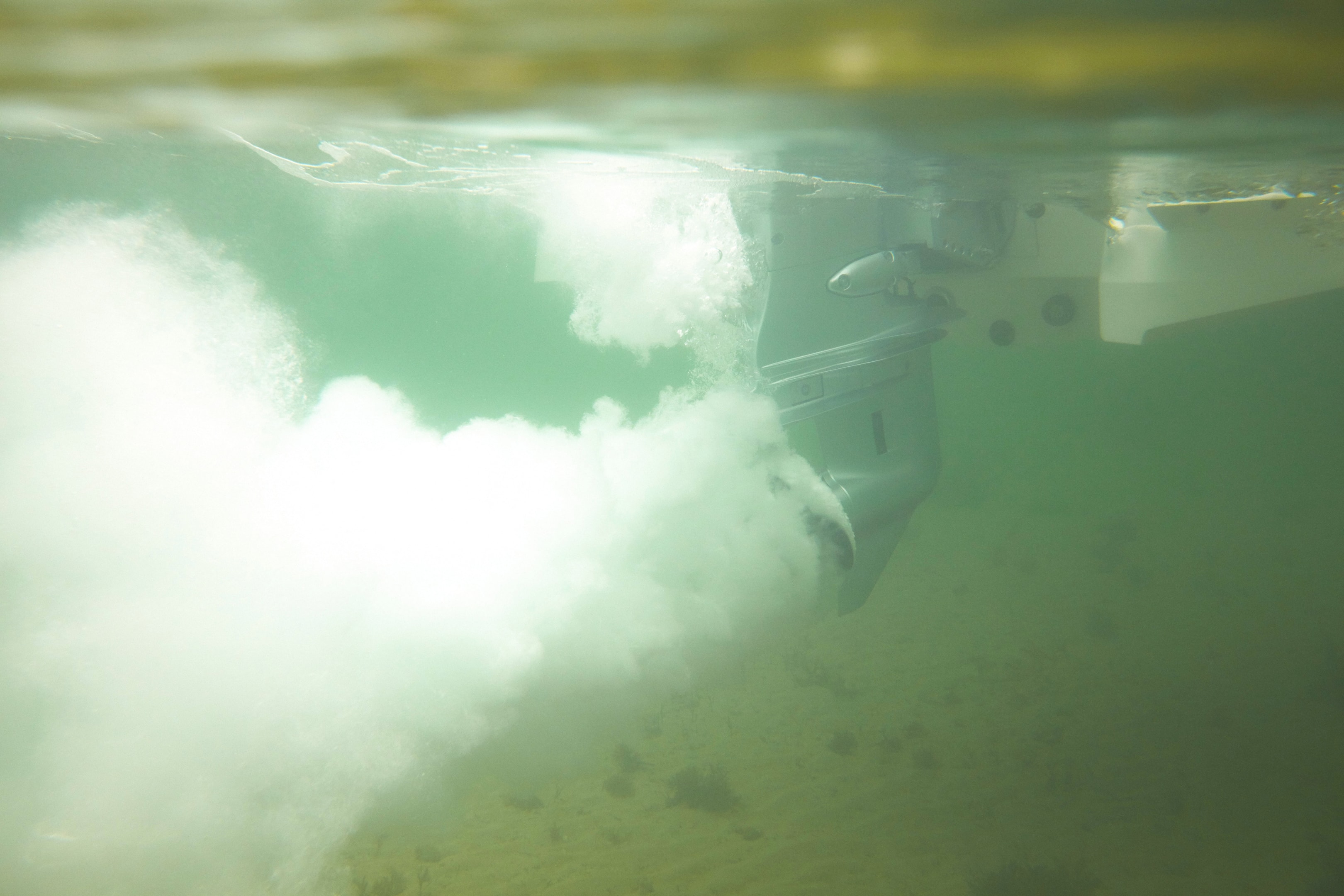

Cavitation: Cavitation is the formation of air bubbles created near the leading edge of the blades, and is often caused by attempting to transmit too much power or speed from the propeller.

Ventilation: Ventilation is the formation of air bubbles created near the leading edge or front side of the blades, mostly due to incorrect running height and trim angle

Efficiency: The blade efficiency is determined by the ratio between thrust and torque.

Understanding Pitch, Rake, Cupping and Propeller Diameter

Pitch and diameter are the vital ingredients. They are the first indicators of performance as they have the major effect on engine RPM. As a general rule, a 1” variance in pitch will produce around 200 RPM variation on a planing hull boat. While this may not necessarily change the overall speed, it will change the performance. A smaller pitch propeller will punch the package out and onto the plane faster due to reduced hydraulic resistance and make the engine rev higher, but may not necessarily improve manoeuvrability or speed due to smaller blade area and diameter.

Blade size and diameter will certainly change the attitude of a boat as they can affect the desired trim angle and engine height. Smaller pitch props generally have larger diameters, particularly for deep water applications, whilst surface piercing or “chopper” props may be very large in diameter to equalise the aeration. Propellers for general purpose production packages will have standard rake and diameter for the pitch of the prop.

Rake plays a large role in a boat's handling as it can noticeably affect the trim. Some hulls like to get the nose up high whilst others, particularly narrow deep-vees, need assistance in getting the transom up and out on the plane. Propeller rake will generally range from slightly forward to an average of around 15 degrees, and many modern props have progressive rake.

Higher rake angles will often assist hulls that create a high amount of aeration, or those that regularly operate in fast flowing streams with high oxygen content. The rake angle has a major impact on centrifugal force which in turn affects the overall efficiency of the prop. Different types of propellers have varying rake angles, and often cupping to improve the propeller's 'grip' on the water. Cupping on a propeller will improve grip but cost you a few top end revs in return.

What is Cavitation and Ventilation?

Cavitation and ventilation are simply pockets of air creating low pressure on the blades of a propeller. They can be caused by the hull itself, the engine height, trim, speed or overpowering. These forces create uneven pressures on the blade surfaces and cause inefficiencies in power and performance, fuel economy, excessive vibration through uneven balance, heightened wear, and may even cause damage to the propeller. Excessive cavitation or ventilation can actually produce substantial heat, damaging or warping the propeller under load.

Ventilation is most often caused by propellers with their engine height too close to the surface drawing in air across the blades. Many hulls produce high quantities of air especially those with uneven or damaged keels, vented strakes, and often the popular rippled pressed alloy hulls. In most cases, ventilation can be reduced or eliminated by dropping the engine lower on its mounting holes.

'Chopper' props and surface piercing drives are actually designed to use their vented design to improve speed. They use the limited restriction throughout the upper half of their diameter to reduce friction while still maintaining terrific propulsion through the bottom arc of the blades. Chopper props have very limited drive at lower speeds, and perhaps even less drive in reverse, but they are extremely efficient in high-speed racing boats.

Left And Right Hand, Counter and Contra Rotation

Most recreational propellers are right hand, i.e. they rotate clockwise when viewed from the stern, providing forward propulsion. However, there are also left hand props (i.e. rotate anti-clockwise) mostly to balance the forces in multiple rig or multi propeller drives, such as a duo-prop stern drive.

In twin engine applications, we use counter rotating engines, whereby the starboard prop is usually right-hand and the port side is left hand – this is often described as outward turning. This configuration equalises the side loading forces for efficient running. It is possible for the roles to be reversed (known as inward-turning) but this is not common on recreational vessels.

Many stern drive legs and some outboard drives use contra-rotating propellers where both propellers are in line yet rotate in opposing directions on a single drive, delivering terrific torque and grip in both forward and reverse gear.

Common Recreational Propellers

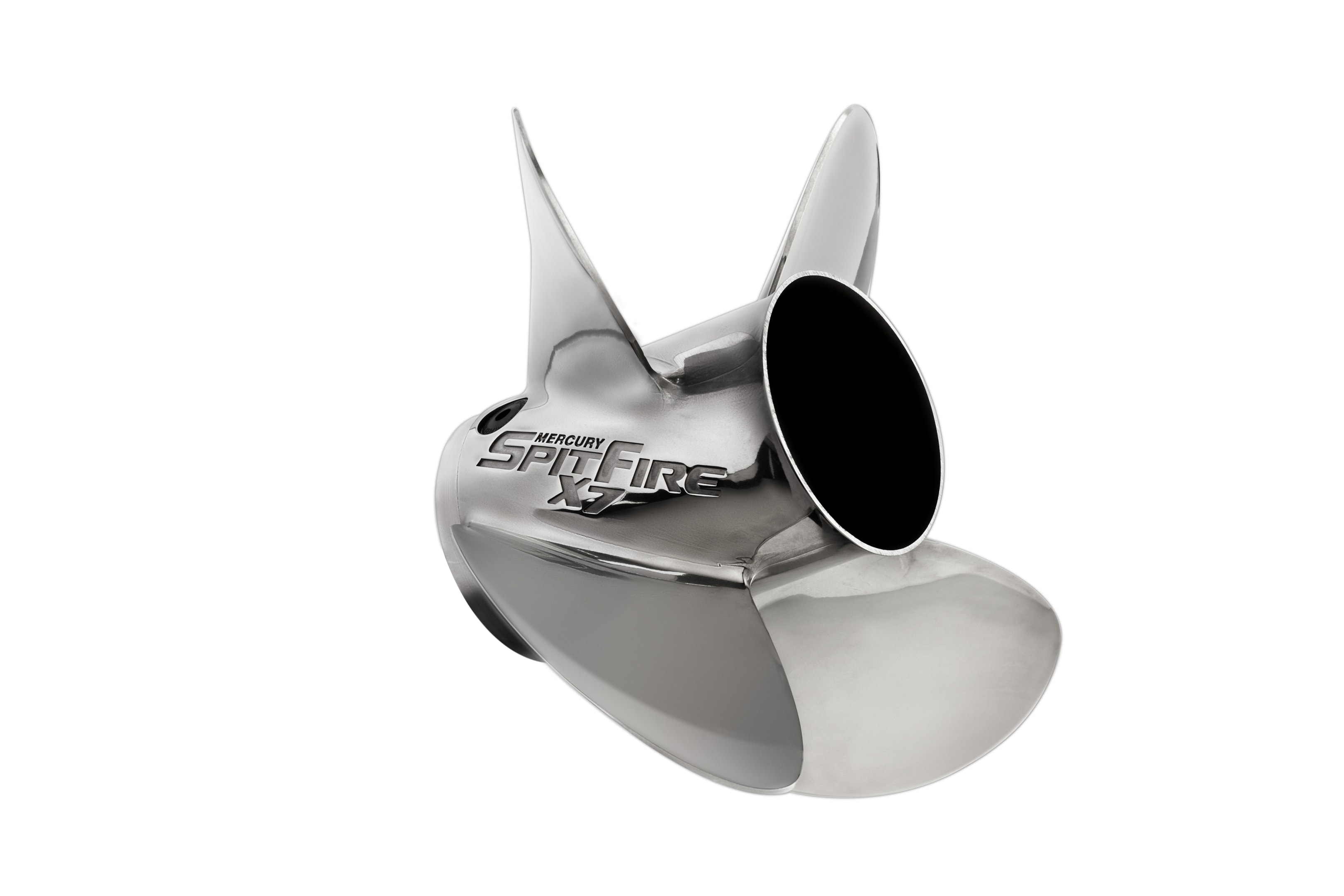

Standard recreational propellers are three or four blade alternatives. These can be made of bronze for shaft driven boats (ski, wake, displacement, planing and cruising) while stainless steel props or aluminium props tend to be used for outboards, stern and pod drives.

Aluminium propellers are the lightest and cheapest of all propellers, and they do a mighty fine job. As a rule, an alloy prop may be 3-4 times cheaper than stainless, and will often run smoother at lower operating range/revs on lower horsepower engines.

Most new outboard engines are supplied with aluminium propellers up to about 115HP, beyond which stainless steel becomes the preferred option. Aluminium props are cheaper, weaker and lighter weight than stainless alternatives and are more prone to damage, corrosion and warping due to the softer metal. Aluminium will often warp under loading which can affect the rake and reduce overall performance, and can be effected by corrosion and wear from cavitation and ventilation. However, alloy propellers are easier to fix by specialist marine repairers should they be damaged.

Stainless steel propellers are obviously stronger, heavier and less prone to warping under load, and are the propeller of choice for higher horsepower and performance outboards. Stainless steel is about five times stronger than aluminium and more impact resistant as a result, providing greater longevity and ability to retain its shape, particularly on the leading edge. There is some advantage to the centrifugal force on the heavier propeller, allowing it maintain higher momentum and torque.

How Many Blades Should You Choose?

Most recreational marine propellers have 2, 3 or 4 blades, with the two bladed items being mainly associated with the retractable or feathering propellers on yachts. Three blade props are by far the most common. They are generally lower cost, give terrific all round performance, have excellent acceleration and good bite in reverse gear.

Four blade props are very popular with the performance and fishing boat fraternity. They are usually made from stainless steel, are more expensive, stronger, and have terrific pushing and holding power with added grip. Four blade propers are usually more fuel efficient than three blade options. The downside, besides the added expense, is that they generally don’t provide as much grip in reverse, drastically reducing low speed manoeuvrability. However, they tend to push heavier packages more effectively.

Alternative Propeller Materials

There is a common conception that you should use an alloy prop when operating around submerged objects, particularly in a backwater fishing scenario, as people would rather damage their alloy prop than transfer the impact loading to the engine. However, most modern propellers have some sort of sacrificial bush which is made to slip under such impact loading. Some of these are in the form of a replaceable pin or hub and others are pressed into place and must be replaced by a technician.

Most shaft driven and V-drives will use bronze or copper alloy propellers, usually on a spline, taper or keyway, and often without sacrificial bushing. Copper alloys can be forged with any number of materials including nickel, manganese and even silica, depending on the application. They are widely used in marine applications because of their resistance to corrosion and ease of manufacture. Bronze alloys are the preferred metal for casting a large range of shaft driven propellers including those for large ships.

Other Propeller Designs

Yachts commonly use feathering or folding propellers that unfold to their drive position under centrifugal force, and fold to minimise drag when under sail.

There have been recent inroads into the use of plastic composite propellers. Although they are lightweight and prone to warping under load, they provide a very realistic and cost effective alternative to metal propellers. The blades of the plastic propellers are usually made thicker to compensate for warping and are generally a little less efficient, but they have excellent corrosion resistance, albeit the tradeoff of limited impact resistance. Overall though, they make excellent spare propellers to the more expensive alternatives.

A controllable-pitch propeller is usually found on large vessels where the pitch can be adjusted according to load, such as in commercial shipping and tug boat applications. Skewback props can actually alter their angles in transit for very limited applications. Modular propellers have been seen in some recreational environments where the prop has replaceable blades, allowing it to be used in different applications.

An example may be where a boat is used for multi-use applications such as fishing to water skiing or wake boarding. Self-pitching propellers are sometimes seen on smaller motors where the blades move freely, allowing the hydraulic and centrifugal forces to self-adjust the blade angles and pitch.

Choosing the Right Propeller

As propellers are your first point of contact with the water, correctly choosing and tuning the propeller is vital to maximising your power, attitude, manoeuvrability, economy and speed, both in forward and reverse gears. Finding the correct propeller is actually like fine tuning the gear ratio.

Maximum horsepower is generally attuned to maximum engine revolutions, and every engine manufacturer quotes the recommended rev range. Staying within this range is essential as a propeller that allows the engine to either over or under rev can cause massive harm to the engine itself. In fact, modern computerised diagnostics could eliminate engine warranties if the prop ratio is not within specifications. Even “pusher” props for heavily laden work boats need to operate in a suitable rev range.

Although boat shops are experienced with propeller selection, technicians don't have the time to test every possible combination. That's why we recommend checking your own boat reaches the optimum rev range with a general wet load. The ideal range is generally within 400 RPM below the maximum RPM, but the closer you can get it the more power and performance will be achieved.

Our Top Propeller Tips

-

Always carry a spare prop.

-

Propellers can be professionally repaired if they sustain minor damage, and can be tuned to deliver better performance.

-

Keep aluminium props painted to avoid them corroding prematurely.

-

Take the prop off and grease the prop shaft regularly to avoid seizing.

-

Have nicks and bent props repaired or replaced ASAP. They reduce the performance of the engine, which can lead to reduced engine life span.

-

When purchasing a prop, let the supplier know what the main purpose of your boating is. Fishing, skiing, and performance boats all require different prop setups.

-

To determine the best prop for your boat, have these details available: the outboard/engine size and brand; the length and weight of your boat; your boat's current maximum RPM and speed.

Additionally, it helps to think about what you want to get out of your propeller. Do you want strong overall performance? A higher top speed? Better handling? More thrust? Getting clear on your goal is the first step to choosing the right propeller.

Start Planning Your Next Adventure with Only Boats

We spend plenty of time worrying about the size, shape, performance and horsepower of our beloved boats but all too often neglect the importance of the propeller. If you're feeling confused by all the terminology, don't fret about it - that's what experts are for, and they'll gladly guide you through everything you need to know in order to choose the right propeller. Before you speak with them, take detailed performance figures on speed and RPM right out to WOT (Wide Open Throttle) to help you out. Quite often some fine tuning, or perhaps even a cupped propeller is all that is needed.

In the meantime, explore our selection of boats for sale and start planning your next escape. Whether you're looking for new boats for sale or used boats for sale, our network helps you find the perfect boat for your budget and lifestyle.

Getting boat finance sorted shouldn't be the hard part of boat ownership. Credit One has helped thousands of Australians get on the water, earning a reputation as Australia's best-reviewed finance broker with 3,000+ glowing Google reviews to show for it. See what customers have experienced by reading their Credit One reviews, or use the loan repayment calculator to work through your options.